|

|

Water Recycling and Reuse All water is recycled. Every drop of water on Earth has been recycled many times through nature's own purification systems. Nature does it using biology, and modern treatment plants work by speeding up nature's own processes in a controlled environment. The most common water recycling method is called the Return Activated Sludge process. It is primarily a biologic system, but also uses basic physical and chemical principles to remove contaminants from water. Use of mechanical or physical systems to treat wastewater is generally referred to as primary treatment, and use of biological processes to provide further treatment is referred to as secondary treatment. Advanced secondary treatment usually involves applying chemical systems in addition to biological ones, such as injecting chlorine to disinfect the water. In most of the United States, wastewater receives both primary and secondary treatment. Tertiary treatment methods are sometimes used after primary and secondary treatment to remove traces of chemicals and dissolved solids. Tertiary treatment is expensive and not widely practiced except where necessary to remove industrial contaminants. The Return Activated Sludge process takes roughly 18-24 hours to turn raw sewage into a valuable resource. Physical processes are the first step in the water recycling process. These include screening, grit removal, and clarification. Raw sewage passes through bar screens which are simply metal rods immersed in the influent flow to separate large objects such as sticks and rags from the water. They are used to protect pumps and other rotating mechanisms further in the treatment process. After the water passes through bar screens, it enters a grit removal system. Here the influent flow is slowed and a mechanical separation of sand and gravel is achieved by systems such as addition of air or inducement of a vortex. Primary clarifiers allow further slowing of the wastewater so that settleable organics precipitate to the bottom while fats, oils, and greases float to the top. These physical processes remove approximately 30 to 40 percent of the contaminants in wastewater.

Biological Systems and Final Clarification Biological processes remove most of the rest of the contaminants. Microorganisms consume the organic material as food, and when it becomes part of their cell mass, it is now converted into a form that will settle out in a final clarifier. The microorganisms do their work in a chamber called an aeration basin, where air is mixed with the water so the bugs have oxygen to survive. Many operators of water recycling plants consider themselves "bug farmers", since they are in the business of growing and harvesting a healthy population of microorganisms. Because the process is biological, any chemical or substance harmful to life can interfere with the operation of the plant. This is why cities prohibit discharges of untreated industrial wastes to sewers and promote education among citizens regarding the harmful effects that dumping household chemicals can have on the treatment process. When the water recycling plant cannot operate properly because chemicals are killing the microorganisms, water reuse programs are jeopardized and the quality of water discharged to receiving streams is lowered.

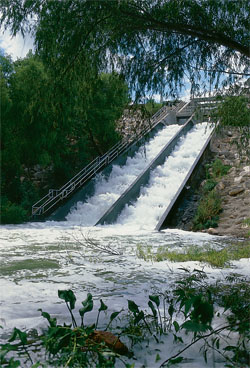

After the bugs do their work and the water is clarified for a second time, chemical systems such as chlorine contact chambers are used to kill the remaining microorganisms not captured in final clarifiers. It is not desireable to have residual chlorine in the rivers and lakes, however, so chlorine is then removed using sulfur dioxide or vigorous aeration. This protects the aquatic life in the receiving stream. Using and storing highly toxic chlorine gas poses risks, so many facilities are beginning to use ultraviolet radiation instead of chlorine to provide final disinfection of water. The point where treated water is discharged into a stream or body of water is called the outfall.

Use of recycled water from water recycling plants can defer large amounts of Edwards Aquifer pumpage during critical times, thereby helping to maintain springflow levels and preserve endangered species habitats. There are plenty of uses that do not require potable Edwards water, such as for irrigation of golf courses and parks, air conditioning cooling towers, and industrial processes. Recycled water contains small amounts of nutrients, so using it in irrigation can reduce fertilizer costs. In other applications such as cooling towers and industrial processes, some treatment and chemical additions may be required, but such is usually the case when potable water is used.

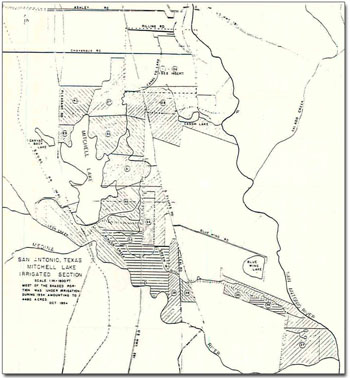

Although reuse can reduce Edwards Aquifer pumping, it can also impact downstream users and aquatic ecosystems by reducing the flow in streams that otherwise would have received the effluent, so careful consideration of all impacts is warranted. Use of recycled water in Texas is classified as either direct, such as by direct delivery from the treatment plant through a pipeline, or indirect, such as delivered via the bed and banks of a river. Reuse In San Antonio: A Long History Few places in the United States have practiced reuse of wastewaters longer than San Antonio. As early as 1894, raw sewage was widely used in agriculture in fields south of town. By 1901, Mitchell Lake had been constructed to capture excess flows that could not be used. By the 1930s, a wastewater treatment plant had been constructed, and both raw and partially treated effluents continued to be delivered to farmlands and to Mitchell Lake through a network of ditches. In 1954, almost 4,500 acres of farmland were being irrigated.

In the 1960s, San Antonio pioneered an innovative use of recycled water in power production. After the drought of record in the 1950s, city leaders looked for ways to conserve potable Edwards supplies. Victor Braunig, then-general manager of City Public Service Energy, the city's electrical generating utility, envisioned that large amounts of potable water could be saved if wastewater effluent was used to cool the city's power plants. Braunig Lake, first filled in 1963, was the world's first large-scale attempt to use recycled water for cooling electrical generating plants. Initially there were some problems with algae and suds from high-phosphate detergents, and large balls of soapy foam were said to have blown across I-37 like tumbleweeds. But Braunig and his staff were determined to make it work, and it ended up working so well that Calaveras Lake was built in 1967. Braunig Lake covers 1,350 acres, and Calaveras Lake covers 3,550. In dry years, up to 50,000 acre-feet of cooling water is consumed that would otherwise have to be drawn from potable supplies or from flows in the San Antonio and Medina Rivers. CPSE withdraws the recycled water from a pump station on the San Antonio River after it is released by SAWS' plants, so the use is classified as indirect.

The Nation's Largest Direct Reuse System In 2000, the San Antonio Water System completed construction of the nation's largest recycled water distribution system. It's purpose is to move fully treated wastewater to locations where it can be beneficially used. Over 130 miles of trunk lines were constructed at a cost of over $140 million. It is classified as a direct reuse project, and water supplied for non-potable uses by this system can supply up to 35,000 acre-feet per year, about 20% of the volume that San Antonio currently withdraws from the Aquifer. In a recycled water distribution system, all piping and appurtenances are required to be purple, in order to differentiate from potable water lines, so the system is often referred to as SAWS' "purple pipe" system. Although reuse is encouraged by the Texas State Water Plan, the state's rules and regulations have not caught up with the 21st century, and for almost a decade SAWS was unable to obtain permits from the Texas Commission on Environmental Quality to allow full utilization of the reuse system. In 2009, the utility was successful in obtaining legislation to allow full utilization, thereby bypassing the regulatory process.

In addition to supplying water to customers for non-potable uses, the SAWS' project was constructed as a unique dual-use system that also involves augmenting the flow of several area waterways. As such, it is one of the largest environmental protection and enhancement projects ever conceived and constructed in the state of Texas. On the San Antonio River in the downtown area, construction of three new discharge points allowed several Edwards wells to be shut off that for many decades had been supplying all the dry-weather flow to the River Walk. A fourth discharge on Salado Creek has re-established a baseflow and created the foundation for a linear aquatic greenbelt (see the Salado Creek page). Since these discharges started, biologists have documented significant and lasting improvements to the aquatic ecosystems in both the San Antonio River and Salado Creek. In the graphic above, note how the system forms almost a complete "water loop" around the city, and that all of SAWS plants are connected to it. The interconnected use of the pipelines and several treatment plants was the aspect of the system that caused heartburn for regulators and prevented SAWS from making full use of the system for almost a decade. Although the concept received strong support from the U.S. Environmental Protection Agency and it even issued a policy statement encouraging "integrated permitting" of treatment facilities for managing discharges on a watershed basis, state regulators in Texas would not go along. SAWS attempted to work with Texas regulators for over eight years to develop a new permitting paradigm that would be a model for the nation. In the end, as mentioned above, SAWS gave up on getting state regulators to see the light and instead solved the problem by successfully seeking new legislation to allow operation of the system as planned. When the distribution system was being designed in the early 1990s, it was sized with a capacity of 35,000 acre-feet per year, so that about 55,000 acre-feet of effluent per year would still be available for maintenance of flow in the San Antonio River. At that time, SAWS' plants were producing about 130,000 acre-feet of effluent per year, and 40,000 acre-feet had already been were dedicated for electrical production. In those days, everyone predicted that wastewater effluents would continue to grow with an expanding population in San Antonio. They didn't. Because citizens have responded so well to conservation initiatives in the last couple of decades, the volume produced by the plants has not increased for over 25 years. But demand for electricity has indeed increased, along with the need for more water to cool the generating plants. So in 2011, SAWS dedicated an additional 10,000 acre-feet to CPS Energy and voluntarily placed a cap of 25,000 acre-feet on the volume that it would distribute annually from the purple pipe system, so there will still be about 50,000 acre-feet per year available to maintain flow in the San Antonio River. SAWS is an active participant in two current legislative initiatives to ensure adequate flow in the River for maintaining a sound ecology. For more on those, see the San Antonio River page.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||